Equipment marketplace

Shopping Cart

0 item(s) - $0.00Buy

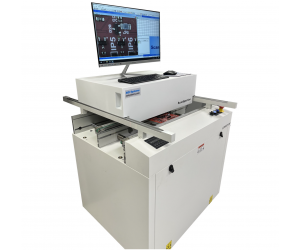

TK1335 - AOI Systems ScanSpection AOI System

Ex Tax: $0.00

AOI Systems (UK) ScanSpection In-line AOI System

Brand: AOI Systems Limited

Model: ScanSpection

Year:

Type: In-line AOI

Automated Optical Inspection

The economic realities of quality control, rework cost and need for customer confidence make Automated Optical Inspection (AOI) a necessity in Circuit Board manufacturing environments AOI can take a number of roles on the PCB production line. There are a number of “captive” applications such as accurate component positioning in the pick and place system, or screen checking in the paste printer, and there are also stand-alone functions to which AOI is ideally suited. AOI Systems ScanSpection uses two basic algorithm groups to inspect component and soldering. The first algorithm checks the component related parameters, with these being entered to a Model training phase. The second algorithm group is for solder and lead inspection and offers the ability to use the optimum algorithm for the type of inspection to be carried out. In addition the solder inspection and lead inspection can be attached to a package type rather than component type to assist in programming.

ScanSpection SS15000PTH (Thru Hole Post & Pre-Wave)

PTH AOI using a high performance line-scan technology. The board is loaded and unloaded using SMEMA conveyor the software uses optical alignment to on-board fiducials maintaining positional accuracy from board to board. Faults reported to panel and board position. All faults can be stored with pictures for use with Scanspections Rework Software. Full fault classification facility for SPC analysis comes as standard. ScanSpections simple programming and user interface ensures that high quality programs can be quickly and easily created for production.

SPC Interface

Data generated can be processed for SPC analysis using either the Excel format or picked up by a predefined worksheet or database. The information is updated and saved using the same part number information as the board program.

Typical Faults Found

Find Typical manufacturing defects - Shifted, Bridging, Damaged, Wrong Polarity, Wrong Part, Missing

Conveyor (mm) (L) 1000 x (W) 50-470

Inspection Area (mm) 420 x 600

Dimensions (mm) 1000 x 1000 x 950

Cycle Time Less Than 20 Seconds (High Speed Mode)

Resolution 20 Micron Standard

Lighting LED

Power Requirements 110.240 Vac 5/10 A

Write a review

Your Name:Your Review: Note: HTML is not translated!

Rating: Bad Good

Enter the code in the box below:

.jpg)